The structure of metal can be inspected using eddy current testing, and the structure test of metal can be carried out at a high speed by establishing an automated system for applications such as poor heat treatment, poor shape test due to mixing of dissimilar materials and missing processing (molding) processes.

Eddyworks’s MFECT(Multi-Frequency Eddy Current Test) Technology allows you to inspect from the surface level to a certain depth level of materials. With the different penetration depths of multi-frequency, it optimizes the structural eddy current test for the various and challenging cases.

It can be used for the heat treatment quality test and detect the material properties after heat treatment such as hardness, case depth, case depth pattern and also structure, tensile strength and etc.

The principle of test is that when the magnetic field generated by the eddy current sensor (coil) is transmitted to the metal close to it, an induced current is generated, which is called an eddy current.

Depending on the physical properties (chemical components) and the degree of structural change of the metal, the size and shape of the eddy current generated in the metal is detected differently, and the equipment detects it and can perform an automated mass production test.

Most metals such as steel, aluminum, SUS, tungsten, copper and alloys can be tested with ECT.

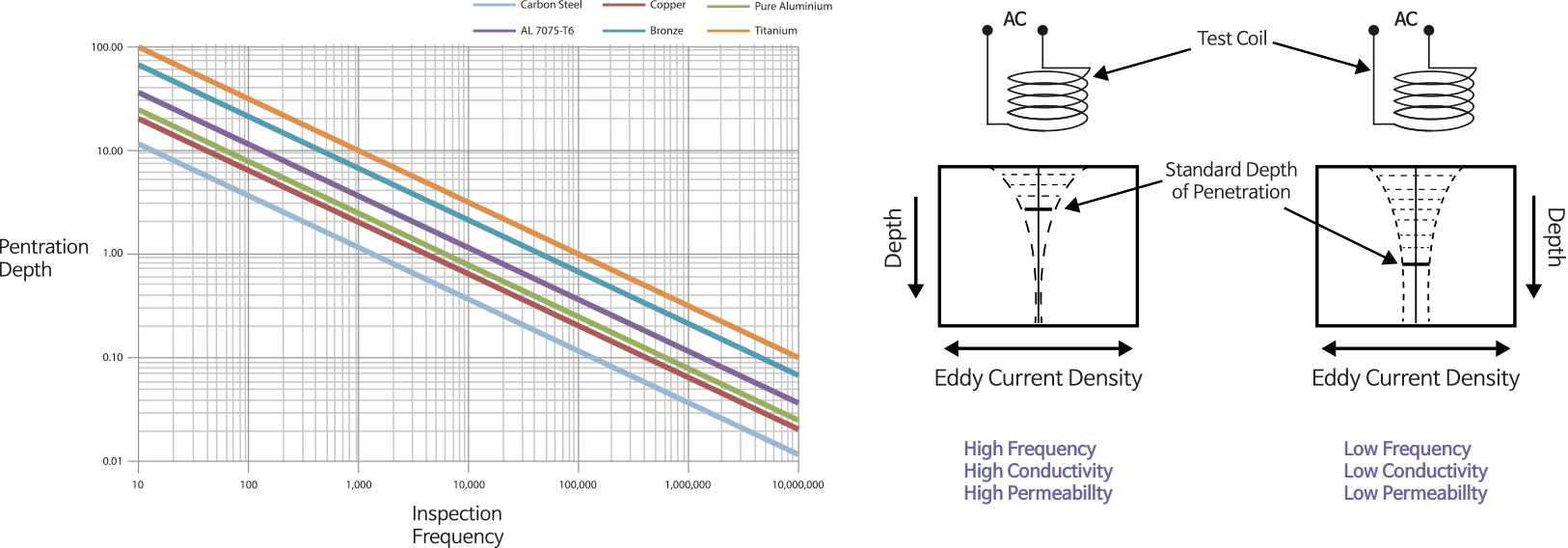

Depending on the material and test frequency, the eddy current penetrating depths are differ as shown in the picture below. The higher frequency has the higher sensitivity to the surface, and the lower frequency can penetrates deeper through the surface to a certain depth.

For this technical reason, Multi Frequency Eddycurrent Testing (MFT/MFETs) can test more different types of defects and challenging ones.

EddyWorks’ equipment can be designed to mix up channels in one equipment with crack detection channels, structure test channels, tap detection channels and their any combinations. And it can simplify the system and lower investment costs.

The test screen provides a cluster screen and a level meter screen of the test signal, and the tested date can be transmitted through communication(LAN. RS232).

The mechanical method of test is determined by the test object and the test location. There are two main methods.

Customized sensors are available for the special shape of the test object.

Mechanical test methods are determined depending on the test item and test location and largely consist of two methods.

Examples of Metal Structure tests

Test object

passing method

(Belt passing method)

검사체 통과방식 (벨트 통과방식)

Test object

passing method

(Chute sliding method)

검사체 통과방식 (슈트 슬라이딩 방식)

Method of inserting and removing a test object or sensor

검사체 또는 센서를 넣어다 빼는 방식

The type of product being tested is not important and if necessary, detection power can be increased by using a dedicate sensor specialized for the tested product.